Introduction

◪ The safety valve test bench is a new type of pressure test device developed by our company for reference to GB/T 12242-2005 (pressure release device and performance test specification), which is used to adjust and test the setting pressure of the safety valve.

Function and features

Safety valve test bench is used for various safety valve setting pressure adjustment, the whole set pressure detection, discharge pressure detection, back seat pressure testing, assessment of its pressure safety performance etc.. ,

◪ A. pressure range: 0-480 bar for option(gas pressure and water pressure)

◪ B. test medium: air, nitrogen, water;

◪ C. test valve diameter: DN15-DN400 for option

◪ D. pressure control accuracy: less than 1%F.S;

◪ E. pressure measurement accuracy: 0.4 pressure gauge (optional higher pressure level);

◪ F. Clamping way: hydraulic cylinder clamping;

◪ G. station interface type: screw and flange type

◪ H. clamping force output range: 0-50 tons;

◪ I. supply voltage: 50Hz -60Hz ,220V/380V for option

◪ J.Size:1500×1200×900mm(machine) +1500×800×800mm(clamping device)

Control panel

Clamping seat

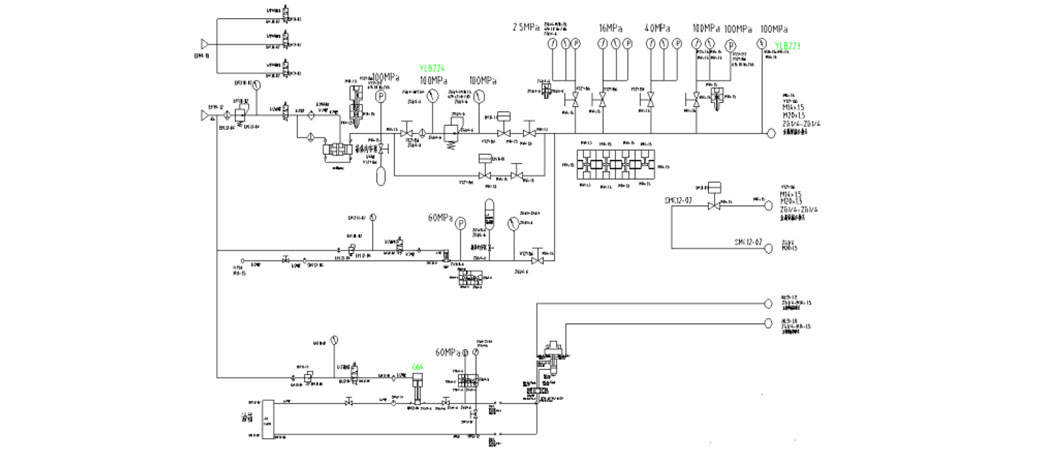

Schematic diagram

Instruction for software control part

◪ Figure 1

◪ The first step: start the computer and double click the boot program, as shown in Figure 1.

◪ The second step: after the program, enter the main interface of the program.

◪ In the main interface, select the appropriate sensor, and pay attention to the selection of the sensor not to exceed the 2/3. of the measuring process ,as shown in Figure3

◪ In the main interface, choose water pressure test or air pressure test. As shown in Figure 4.

◪ After selecting the pressure or water pressure test, click the menu bar test information to set the options. As shown in Figure 5.

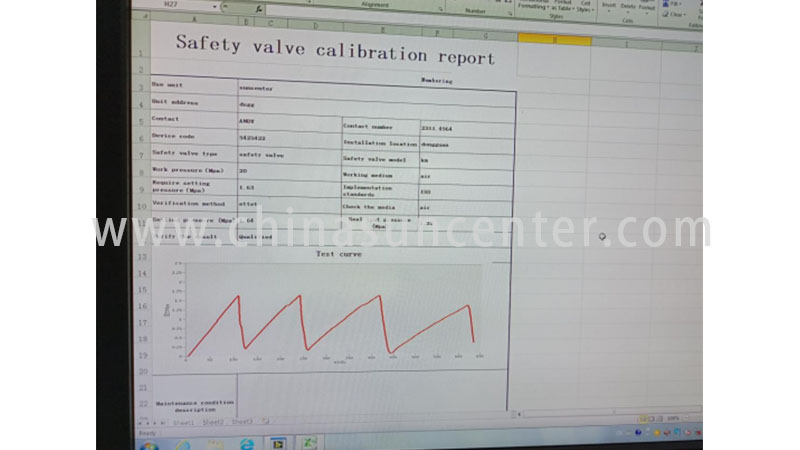

◪ Display the dialog box for the test information, as shown in Figure6

With printer,could print the testing report directly.

◪ Safety valve test bench SVT40-DN400-CC computer control model

video

Авторские права © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | Все права защищены