Cylinder hydrostatic pressure test machine

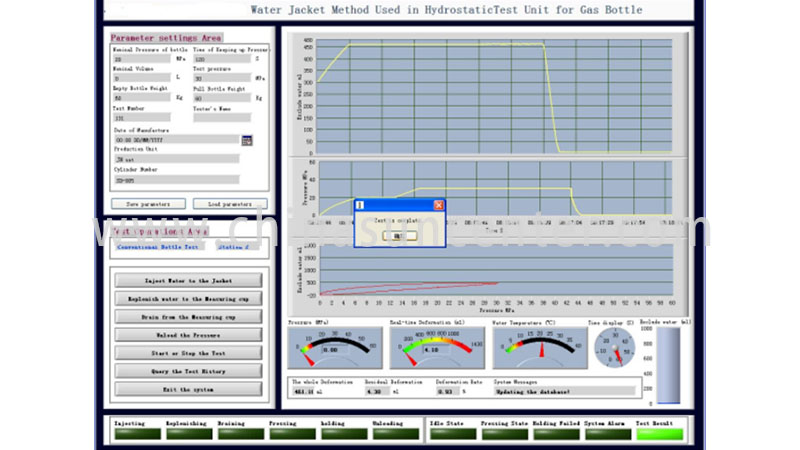

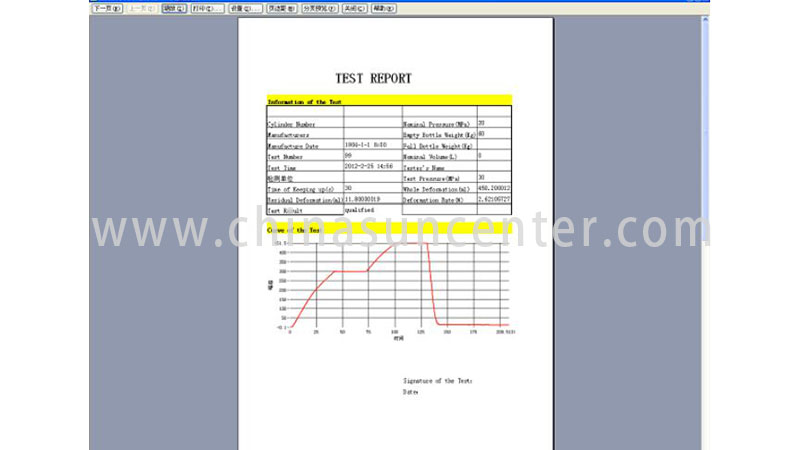

Suncenter cylinder hydrostatic testing machine is suitable for the most seamless steel cylinder, including: nitrogen cylinder, argon helium cylinders, oxygen cylinders, hydrogen cylinders, carbon dioxide cylinders, LPG/LNG/CNG winding bottle, liquefied gas cylinder etc.. The equipment is controlled by computer, equipped with HP printer to directly print the test report, double water jacket for oxygen bottles and other cylinders, cylinders are widely used in testing station cylinder jacket method of hydrostatic test evaluation.

The machine is mainly used for cylinder pressure test and achievement of gas cylinder volume residual deformation rate.

Working principle

Put the cylinder into a water jacket and boost the cylinder by high pressure pump. It will automatically dwell at set pressure and do pressure test on the cylinder. At the same time, the cylinder volume expands under test pressure and squeezed some water from water jacket into the measuring cup, and it is test cylinder volume deformation. The water is transferred to PC by water collection system, the elastic deformation disappears after cylinder relief of pressure, then the water flows back from measuring cup to water jacket. However, the remainning water in the measuring cup is still more than that before boosting the cylinder. The extra water volume is the test gas cylinder volume residual deformation. While the gas cylinder volume residual deformation rate is the ratio of the test gas cylinder volume residual deformation and all deformation.

video

Авторские права © 2025 Dongguan Suncenter Fluid Control Equipment Co., Ltd. | Все права защищены